Truck and Vehicle Wash Systems

SUPER WASH | Mine haul vehicles and mining equipmentThe Mine Haul Super wash is a custom built super heavy vehicle wash system designed specifically for mine haul vehicles including loaders, excavators and equipment - wheeled or tracked. Each system is custom designed by our engineering team to meet the operational requirements of the mine, minimise downtime, ensure environmental compliance and meet site safety and health requirements. The Mine Haul Super wash utilises water technology that can be fully automated to speed up the wash process ensuring minimised maintenance washing for maximum productivity. Available options: Automated cannon wash system - Automated pressure wash system- Dumper wash – Water treatment system – Automated Traffic Management System – Remote monitoring- Heavy sediment separation – Auto waste recovery and return to stockpile |

|

Deluge CB | Light and Heavy Vehicles - PermanentUnderstandably one of the most popular models in the Fleetwash range, the Deluge CB is a powerhouse wash system that has the capacity to wash 24 hours per day. |

|

Deluge R | Light and Heavy Vehicle - RelocatableA fully relocatable version of the Deluge CB, the DELUGE R is a powerhouse wash system that has the capacity to wash 100 vehicles per hour with the added benefit of being transported around the operational site as required, an excellent Heavy Duty and long term investment for a growing facility. |

|

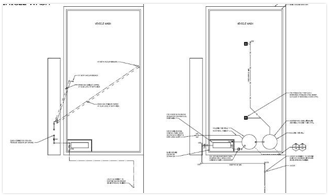

Cyclone R | Light Vehicle, Heavy Vehicle and Constructions TrafficThe cyclone range is designed for uses in all areas of mining and construction and is built to provide an effective under chassis, wheel and tyre wash for all types of road registered vehicles. The Cyclone range comes in a number of models allowing flexibility to provide permanent wash solution or completely relocatable. The Cyclone range can be upgraded to the Hurricane or Tornado models for increased power and perfoamce to meet the needs of the site. The Cyclone range wash is perfect for maintenance control and environmental control of road registered vehicles entering public road ways. |

|

Fleetwash Rumble Grids | The ThundergridFleetwash rumble grids, which we call the Thundergrid, are engineered to provide a low cost, effective and portable solution to stop track out from your work site and reduce mud and debris accumulating on vehicle tyres. Where the area surrounding your worksite needs to be protected, the Thundergrid has a role and this is of particular interest for worksites utilising council roads. Suitable for: Construction work sites where vehicle track is required to be minimised. |

|

EZ Wash | Parts and Equipment WashThe mine ready parts and equipment wash is a portable solution to onsite maintenance wash requirements. Built specifically for 'at location' wash readiness, the heavy parts and equipment wash can be relocated for immediate wash capabilities removing the requirement for large parts and equipment to be transferred to the in situ wash facility for cleaning. This investment in your maintenance infrastructure will increase productivity in both personnel and equipment. |

|

Custom | Wash Bay Design, Approval and ConstructWash Bay Design

|

|